Nuclear power plant VR maintenance training system

-

Task

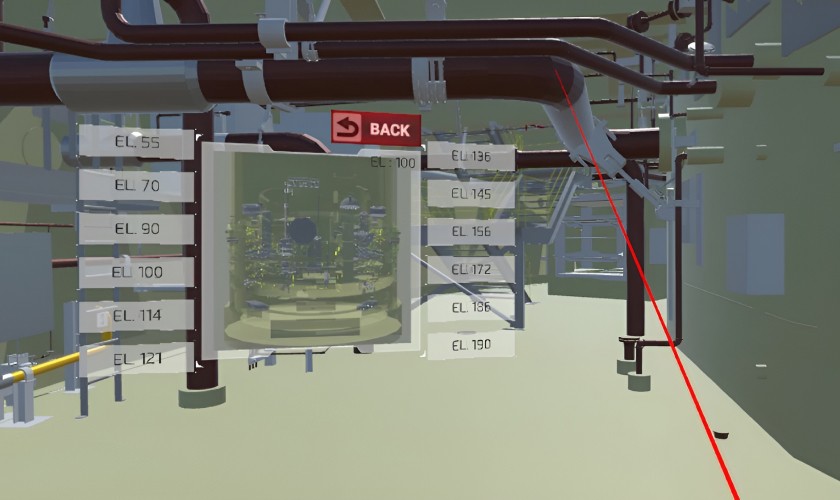

Customer needs to conduct maintenance and safety training with VR devices.

Project purpose to inquire the Equipment information through the training system and to learn the optimal movement path in case of disaster and crisis situations. -

Solution

By linking the internal shape of the nuclear power plant with VR, it guides users to escape routes based on the radioactivity level and location information of the facility.

In addition to simple route guidance, you can check the facility's attribute information and maintenance details. -

Benefit

Reducing the risk of safety accidents through untact escape training.

Reduce training operational costs by reducing on-site training period.

Y OIL & GAS Solution company

Virtual Plant Equipment and

Sensor Integrated Monitoring Solution

-

Task

Customer needs for additional features that allowed workers to collaborate while monitoring plant facilities and sensor data in real time on the metaverse.

-

Solution

In addition to plant monitoring within the metaverse space, real-time status of sensors such as installation and removal, can be monitored through dashboards.

Multilateral communication is also possible using functions such as chat, file download, and whiteboard. -

Benefit

Support quick and accurate decision-making by equipment installation simulation.

Increase efficiency of Information delivery through untact cooperation.